Motors

Motors are the driving element within the actuators that power every joint in a humanoid robot. They determine torque, precision, efficiency, and responsiveness — key factors in how the actuator performs. The choice of motor — whether brushless DC (BLDC), stepper, or torque-controlled — directly affects agility, payload, and battery life.

Recent designs focus on higher torque density, better thermal management, and tighter integration. Quasi-direct-drive architectures reduce gear complexity while enabling fine force control.

Axial-flux motors with foil windings improve torque output in compact volumes, with commercial examples achieving torque densities of 20–28 Nm/kg. Integrated motor drives (IMDs) combine power electronics and advanced cooling, pushing torque density to 4–10 Nm/kg in recent quasi-direct-drive actuator designs.

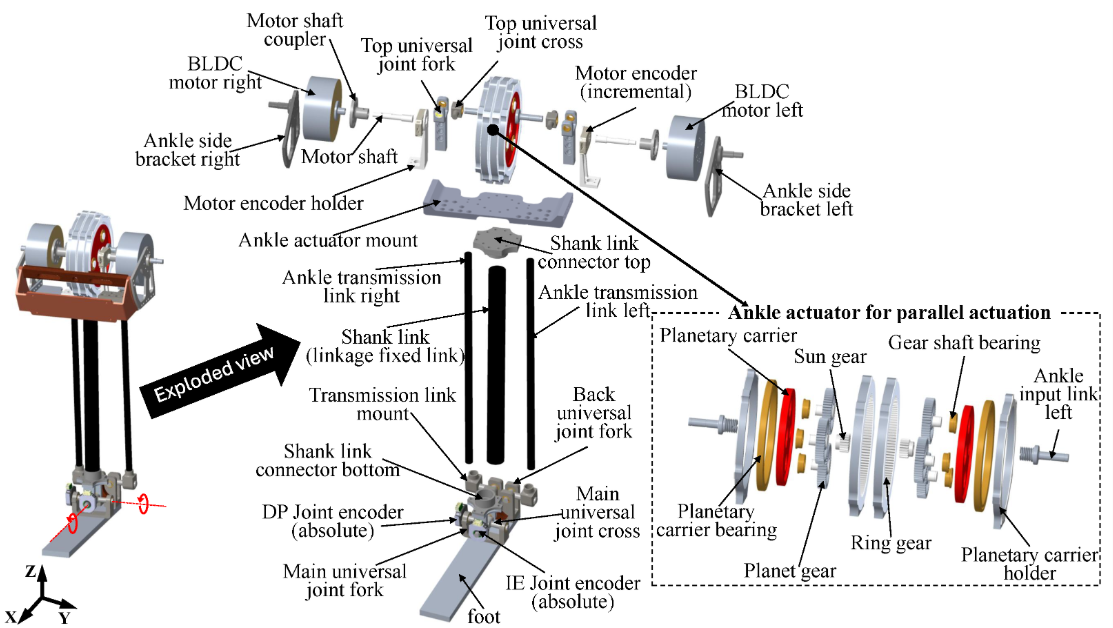

High-torque modular design: The Mithra humanoid uses quasi-direct-drive ankle actuators with BLDC motors and torque sensing to support compact, agile 2-DoF control for dynamic walking. Source: Design of Actuators for a Humanoid Robot with Anthropomorphic Characteristics and Running Capability

High-frequency winding methods are also improving the speed–torque tradeoff critical for real-time physical interaction.