Research

The Future of Humanoid Warehouse Automation: A 2028 Market Outlook

The warehouse automation landscape is undergoing a swift transformation, with technology reshaping how businesses approach logistics and fulfillment.

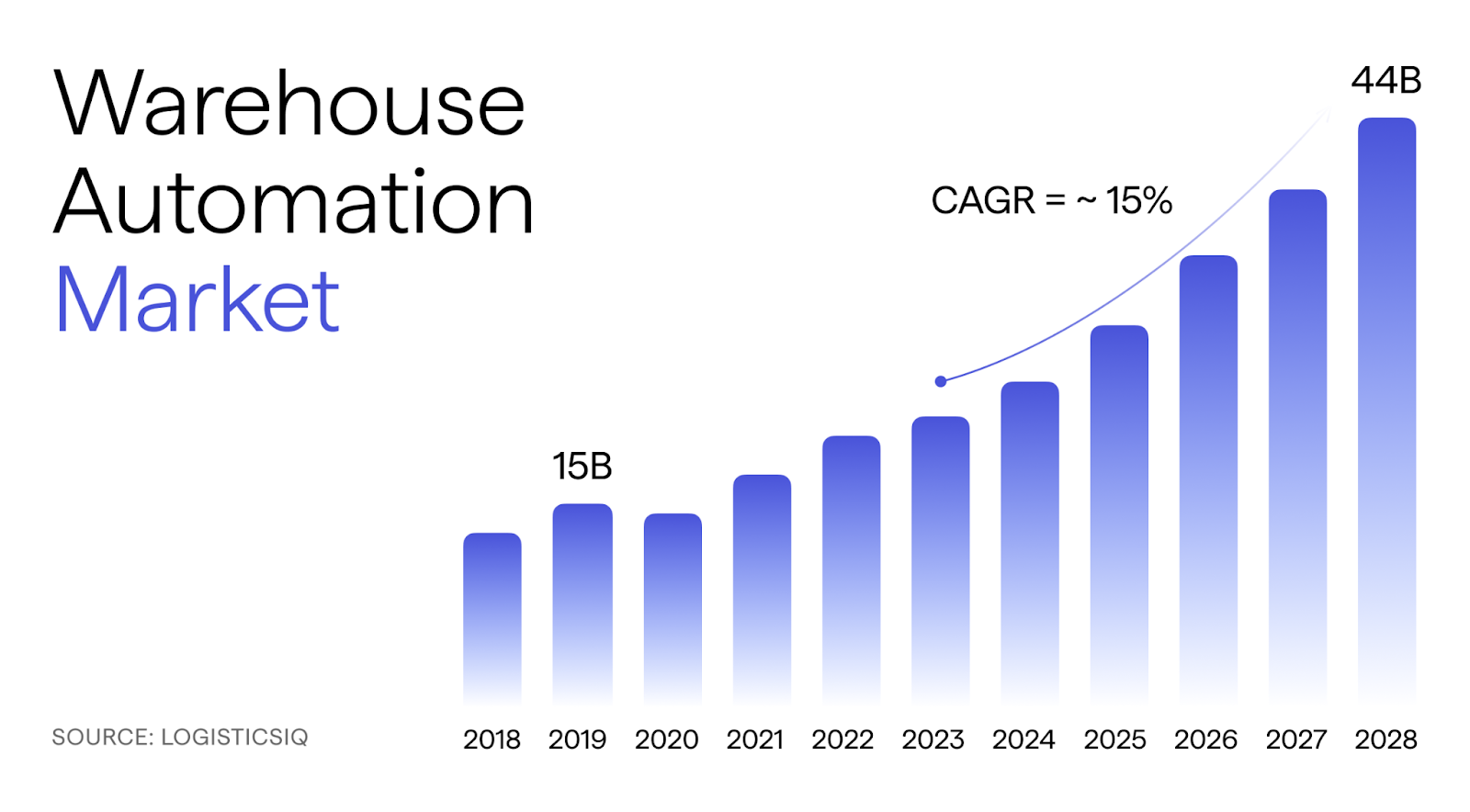

The latest data shows the global Warehouse Automation Market is poised for explosive growth, projected to reach $44 billion by 2028 according to the LogisticsIQ report for 2024, which represents a 15% Compound Annual Growth Rate (CAGR).

At Humanoid, we view warehouse automation as a critical frontier for robotics technology, where advanced humanoid robots with sophisticated manipulation capabilities and adaptive learning algorithms can seamlessly integrate into complex logistics environments. This is the environment where humanoids are uniquely positioned to transform traditional warehouse operations through their ability to perform intricate tasks with human-like dexterity and precision while offering unprecedented scalability and operational flexibility.

Global Market Dynamics

Currently valued at approximately $20 billion in 2023, this market segment is expected to reach $44 billion by 2028.

Source: https://www.thelogisticsiq.com/research/warehouse-automation-market/

It is predominantly driven by three powerhouse countries: the United States, China, and Germany. These nations not only drive over 50% of the market demand, but also host the majority of Original Equipment Manufacturers (OEMs) and system integrators.

While Western Europe accounts for nearly 30% of the global market, some of the most promising growth trajectories are emerging in the Asia-Pacific region, particularly in South Asia and Southeast Asia.

Emerging markets like India are also becoming hotspots for warehouse automation innovation.

Technological Revolution: AGVs and AMRs Leading the Charge

A standout trend is the rise of Autonomous Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs).

These technologies are expected to capture more than 20% of the market by 2028, with an impressive CAGR of around 30%.

The flexibility of AMRs, which can deploy without significant infrastructure modifications, makes them particularly attractive for small and medium warehouses.

Along with growing demand, we’ve seen substantial investments in innovative startups like Symbotic, Takeoff Technologies, and Geek+, alongside established players such as Dematic, Honeywell Intelligrated, and AutoStore.

Emerging Business Models and Market Opportunities

One of the most interesting developments we’ve seen in recent years is the shift towards Robotics-as-a-Service (RaaS).

This model offers businesses lower entry costs and greater flexibility, with pricing ranging from 6-10 cents per pick or monthly robot leasing rates between $750 to several thousand dollars.

The pandemic has been a catalyst for transformative changes in warehouse automation, dramatically accelerating several key trends that are reshaping the logistics landscape.

Specifically, the global health crisis has rapidly propelled the growth of eGrocery, driven the emergence of micro-fulfillment centers, and sparked increased investment in automated picking technologies.

Innovations like mixed pallet automation, mobile manipulators, and automated cold storage have transitioned from experimental concepts to practical solutions, enabling businesses to enhance operational efficiency, reduce labor dependency, and maintain resilient supply chains.

These developments are not just technological advancements, but strategic responses to unprecedented market disruptions, demonstrating how adaptability and technological innovation can transform challenges into opportunities for growth and optimization.

Limitations of Existing Solutions

Current warehouse automation solutions, while effective, face several limitations that humanoid robots could potentially overcome. Traditional automated systems often lack flexibility and adaptability, struggling with tasks that require human-like dexterity or decision-making.

For instance, robotic arms and conveyor systems are efficient for repetitive tasks, but struggle with irregularly shaped objects or dynamic environments.

Here’s where humanoid robots, with their advanced manipulation capabilities and adaptive learning algorithms, can offer a promising solution to these challenges. They can potentially handle a wider range of tasks, from picking and packing to complex assembly, with greater flexibility.

And their human-like form factor allows them to operate in environments designed for human workers, reducing the need for extensive warehouse modifications.

Humanoid Robots to the Rescue

Humanoid robots offer promising applications in warehouse environments, including versatile task handling, collaborative work, adaptive learning, and complex manipulation. These robots can perform various tasks such as sorting, packing, and inventory management with unprecedented flexibility.

Their advanced sensors and AI enable them to work alongside human employees, enhancing productivity and safety.Equipped with machine learning capabilities, humanoid robots can continuously improve their performance and adapt to new tasks or changing warehouse layouts. Their dexterous hands and arms allow them to handle delicate or irregularly shaped items that challenge traditional automation systems.

Major companies explore humanoid robots’ potential to enhance efficiency and address labor shortages in the logistics industry. Amazon has been testing robots at its warehouses for years, including the introduction of Agility Robotics’ Digit, designed to move empty tote boxes in fulfillment centers. Tesla has introduced Optimus Robot, which can sort objects autonomously and self-calibrate its arms and legs.

Agility Robotics has similarly deployed its Digit humanoid robots at a Spanx facility in Georgia under a multi-year agreement with GXO Logistics.

Looking Ahead

With a projected $11 billion services market by 2028 and growing interest from retailers and logistics providers, warehouse automation is no longer a futuristic concept—it’s a present-day necessity.

As e-commerce continues to expand and supply chain efficiency becomes increasingly critical, the warehouse of tomorrow is being built today.

In the next five years, we envision warehouses transformed into dynamic ecosystems where humanoid robots work seamlessly alongside human workers, adapting in real-time to complex logistical challenges. These human-like robots will become the backbone of modern logistics, moving with grace and precision through warehouse aisles, handling everything from delicate electronics to bulky packages, while continuously learning and optimizing their performance.

As AI breakthroughs propel us into a new era of intelligent automation, humanoid robots will emerge as transformative partners in warehouse operations, seamlessly blending human-like adaptability with machine precision to revolutionize how we approach complex logistics challenges.

With their ability to intuitively sort, pack, manage inventory, and collaborate in real-time, these robots will not just enhance workplace efficiency, but fundamentally redefine the potential of human-machine teamwork, creating workspaces where innovation, flexibility, and intelligent problem-solving become the new standard.